- Resources

- Tackling flaring: Learnings from leading Permian operators

Resources

Tackling flaring: Learnings from leading Permian operators

Published: June 9, 2020 by EDF Staff

Natural gas flaring has been a long-time concern for the oil & gas industry. In a decarbonizing world and increasingly competitive energy industry, eliminating routine flaring is critical to minimize climate impact and curtail economic waste.

As the Permian Basin witnessed a rapid growth in oil production over the past decade, the rate of routine natural gas flaring also increased at an alarming rate.

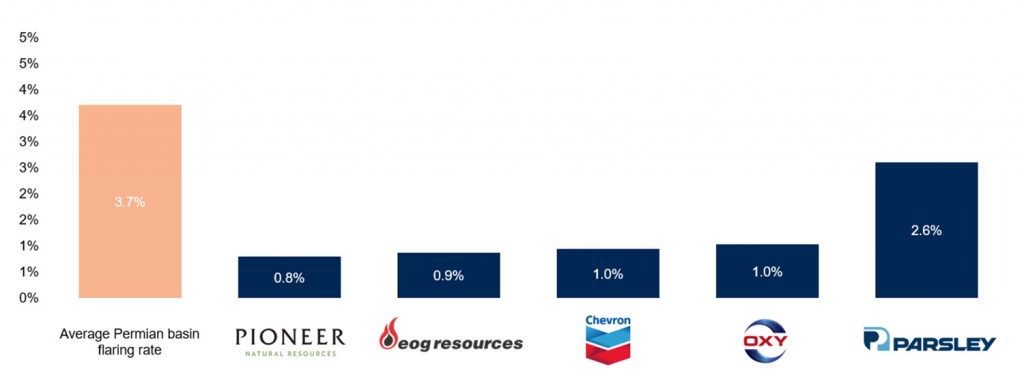

While flaring is a widespread industry problem, several Permian producers have found solutions to effectively minimizing flaring, achieving flaring intensity rates from less than 1% to 2.6% in the Permian, where the basin average is close to 4%.

Based on interviews with several of these Permian producers, this report outlines feasible and effective solutions to minimize flaring. Industry and other stakeholders can learn from these best-in-class producers to accelerate action and cost-effectively implement flaring solutions.

Despite complex economic and infrastructure issues, as exemplified by these operators, solutions to eliminate natural gas flaring exist. But individual actions alone are not sufficient. Eliminating routine flaring will require collective action. This report highlights the opportunity for policymakers, investors, and other industry stakeholders to play an active role to achieve industry-wide flaring reductions.

Key finding 1

Build a culture focused on flaring reductions through strong governance and environmental leadership

Establishing a governance structure and culture focused on eliminating flaring drives low flaring rates. Operators can create this industry focus at the executive and operational level through actions such as setting reduction targets, establishing internal training programs and working committees to share best practices and making flaring intensity data transparently available to employees.

Key finding 2

Reduce flaring in the first place by ensuring sufficient takeaway capacity before wells come online

- While lack of takeaway capacity is the most frequent reason used to justify flaring, best-in-class producers illustrate that this is not a sufficient reason to routinely flare. The producers in this study attribute their top-tier performance to the strategic decision to ensure sufficient pipeline takeaway capacity is available before bringing a well into production.

- Producers can secure this takeaway by collaborating closely with midstream companies to establish long-term, strategic partnerships or by investing in an integrated model to own and operate their own gathering and processing systems.

Key finding 3

Implement robust operational practices when flaring must occur to ensure flare functionality and reduced emissions

Due to operational upsets, sometimes flaring must occur. Best-in-class operators employ a range of solutions to ensure flare functionality, including utilizing continuous monitoring systems, strategically designing escalation processes to ensure timely responses, and installing vapor recovery units to prevent unplanned gas venting.

The bottom line: beyond being economically wasteful, flaring impacts industry financials

Investors are under increasing pressure to see strong ESG performance from their energy portfolio. Producers in this study recognized that robust flaring management supports their financial positions by protecting cash flow, mitigating investment risk, and protecting access to capital markets.

Tackling flaring: Learnings from leading Permian operators

As investors take a sharp look at industry investments during this challenging time, the financial and ESG case for reducing flaring has never been more important.

View the webinar

About this report

The report was authored by GaffneyCline, a global consultancy to the oil and gas sector. EDF appreciates Chevron, EOG Resources, Occidental, Parsley Energy, Pioneer Natural Resources and University Lands for sharing their experiences on flaring.

-

Investor Climate Insights HubLearn more

-

Sustainable Finance NewsletterSign up for updates